BUILT

BETTER.

Next generation

building and living.

Made in Alaska and used in over 1,000 homes and structures, our Structural Insulated Panels provide superior performance and an elevated experience in your next structure.

Energy Saving

Our Alaska Building Energy Efficiency Standard 6-Star+ rating is achieved through our exceptional 6.5-inch, R44-rated panel, resulting in a structure that is more than twice as efficient as typical new construction, leading to a significant reduction on heating needs.

Structurally Superior

Our SIP structures surpass code requirements for snow load, wind, and shear strength in Alaska. They are designed, engineered, and university-tested, showcasing superior integrity compared to stick frame construction.

UL Class 1 Fire Rating

Our closed-cell foam chemistry boasts a UL Class 1 Fire Rating, ensuring the highest level of insulation safety. Unlike commonly used insulation in homes and structures, an electrical fire in our SIP wall system cannot propagate through the insulation, providing enhanced safety.

Construction Speed

Our construction assembly is quicker than standard stick frame builds, saving time, enhancing safety, and lowering the overall cost per build. Our packages are efficiently shipped, reducing transportation and logistics expenses for your new structure.

Fit & Finish

Our panels feature manufactured electrical pathways, offering flexibility for various finish preferences. Enhanced by the superior passive sound isolation of our SIPs, the outcome is a quieter, top-tier structure.

Simplicity & Flexibility

Our high-strength SIPs provide the opportunity to customize your space without the hassle of finding studs. With unmatched flexibility, our panels come in various sizes and R-values ranging from R29 to R60.

Superior chemistry

Our superior closed-cell polyurethane foam doesn’t absorb water, eliminating potential mold issues in your structure or home.

20+ years experience

As Alaska’s leading SIP manufacturer, we have over a two decades of experience you can trust, producing over 30,000 panels that are currently in use throughout Alaska in over 1,000 homes and structures.

Our custom foam-blend is injected into panel molds at high pressure, creating an eco-friendly structural insulated panel.

The result is

a highly efficient structure that delivers remarkable energy savings

and greater strength than stick frame construction.

OR

BUY

PANELS

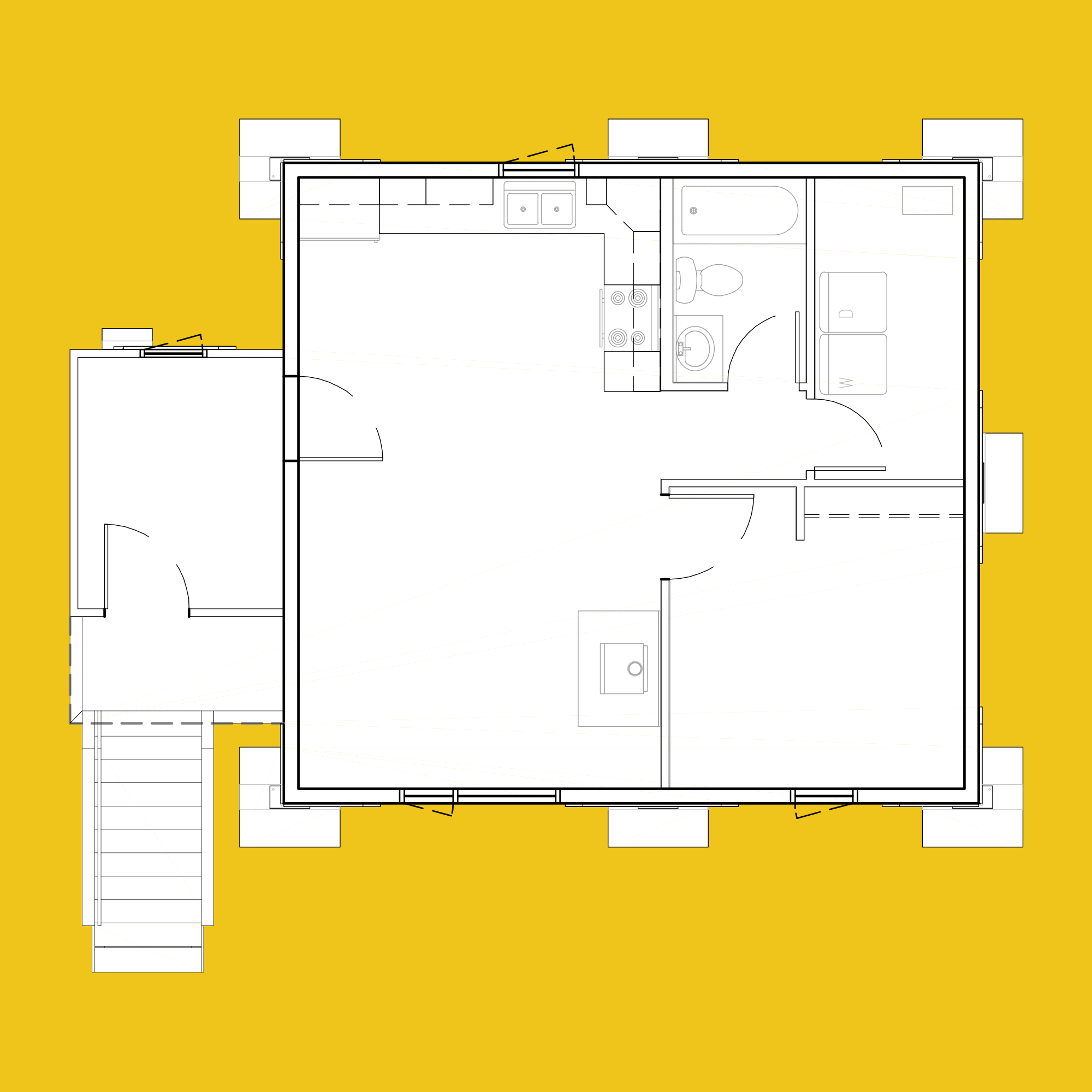

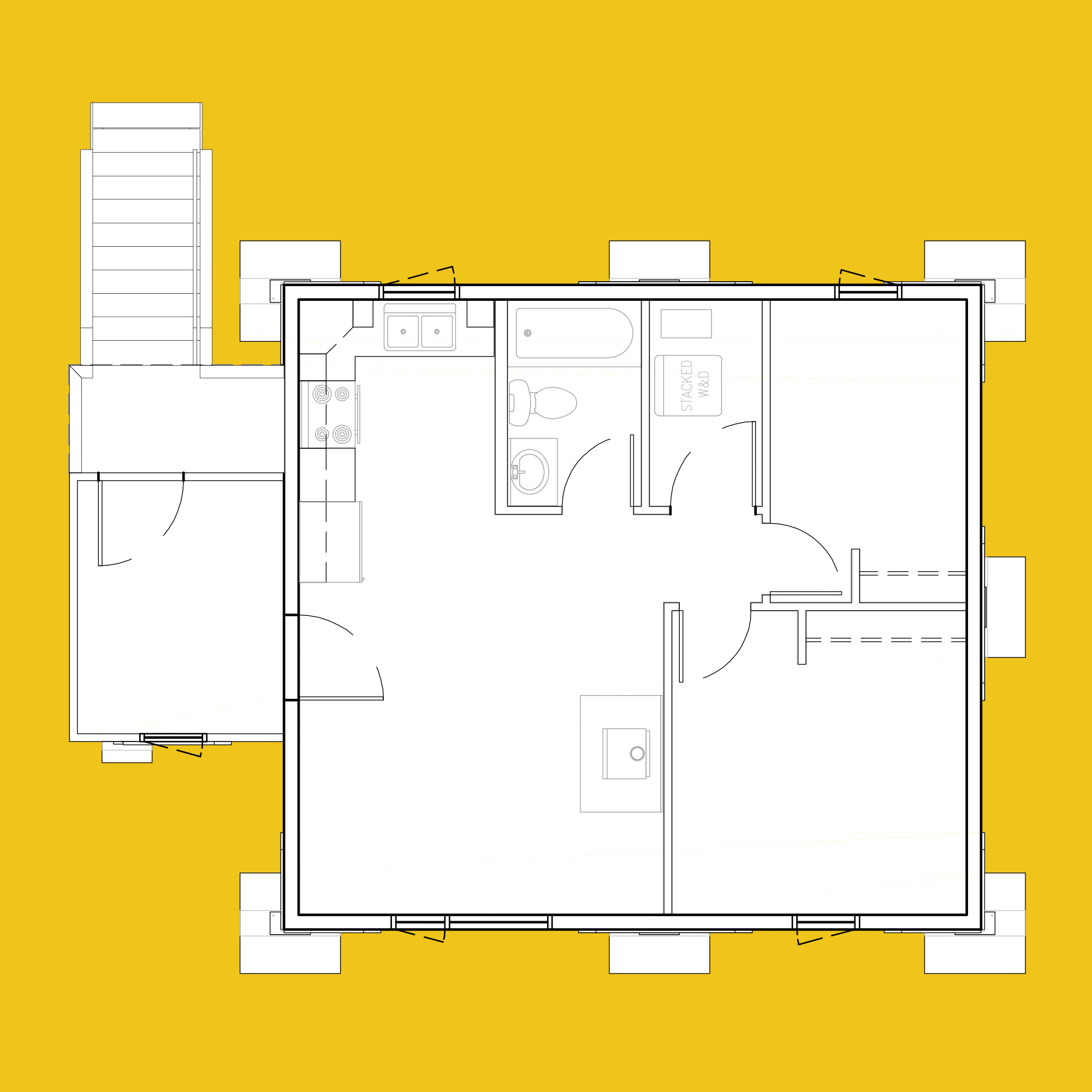

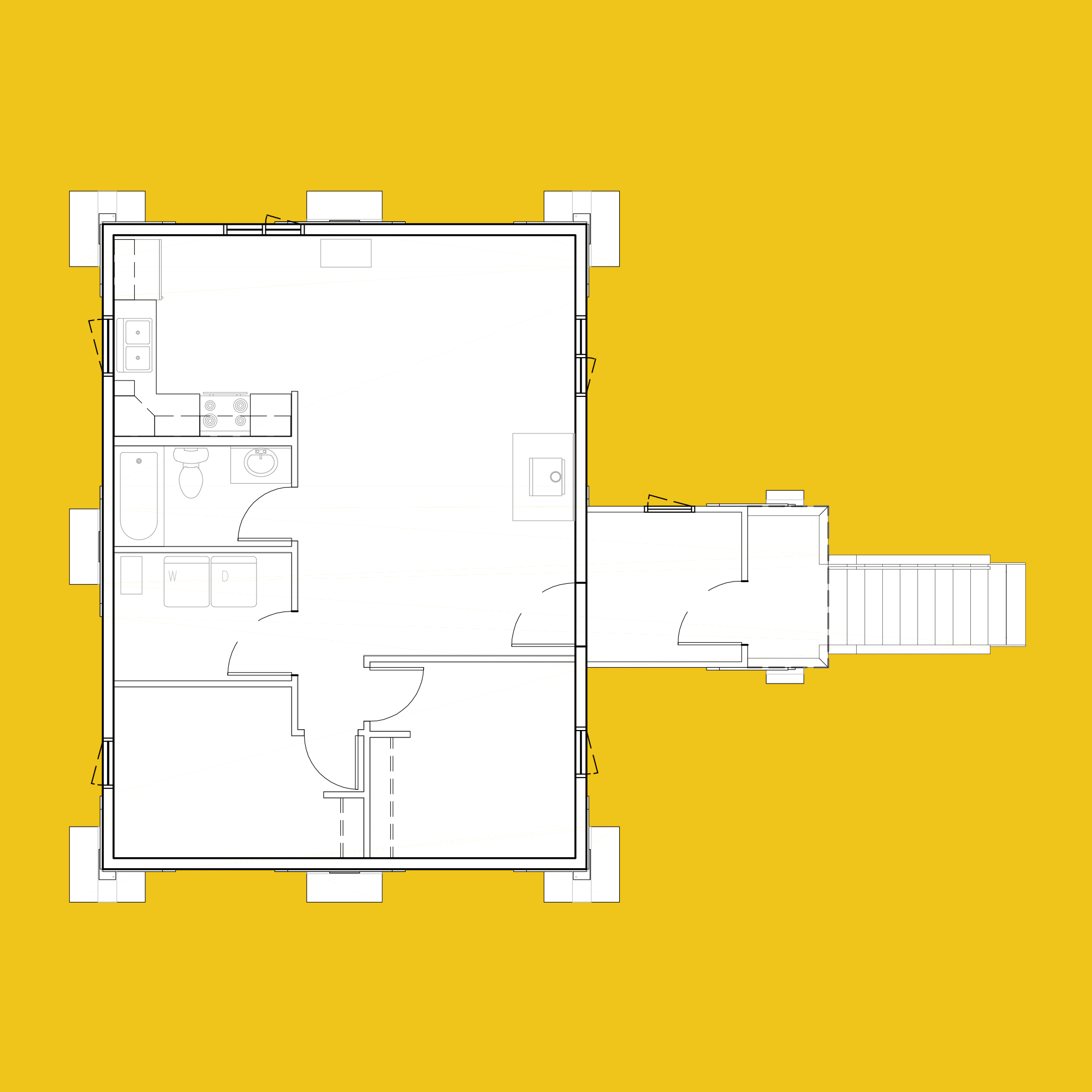

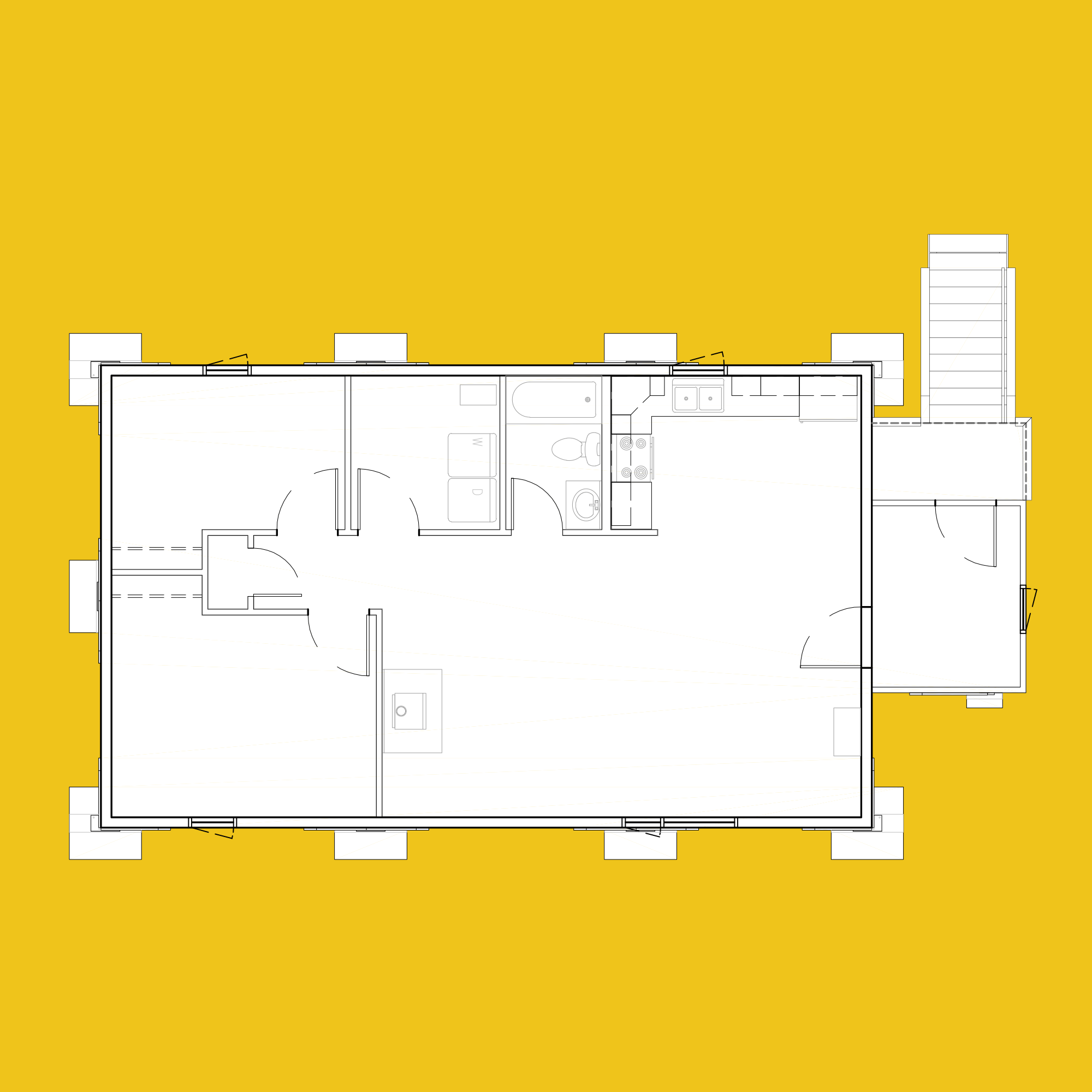

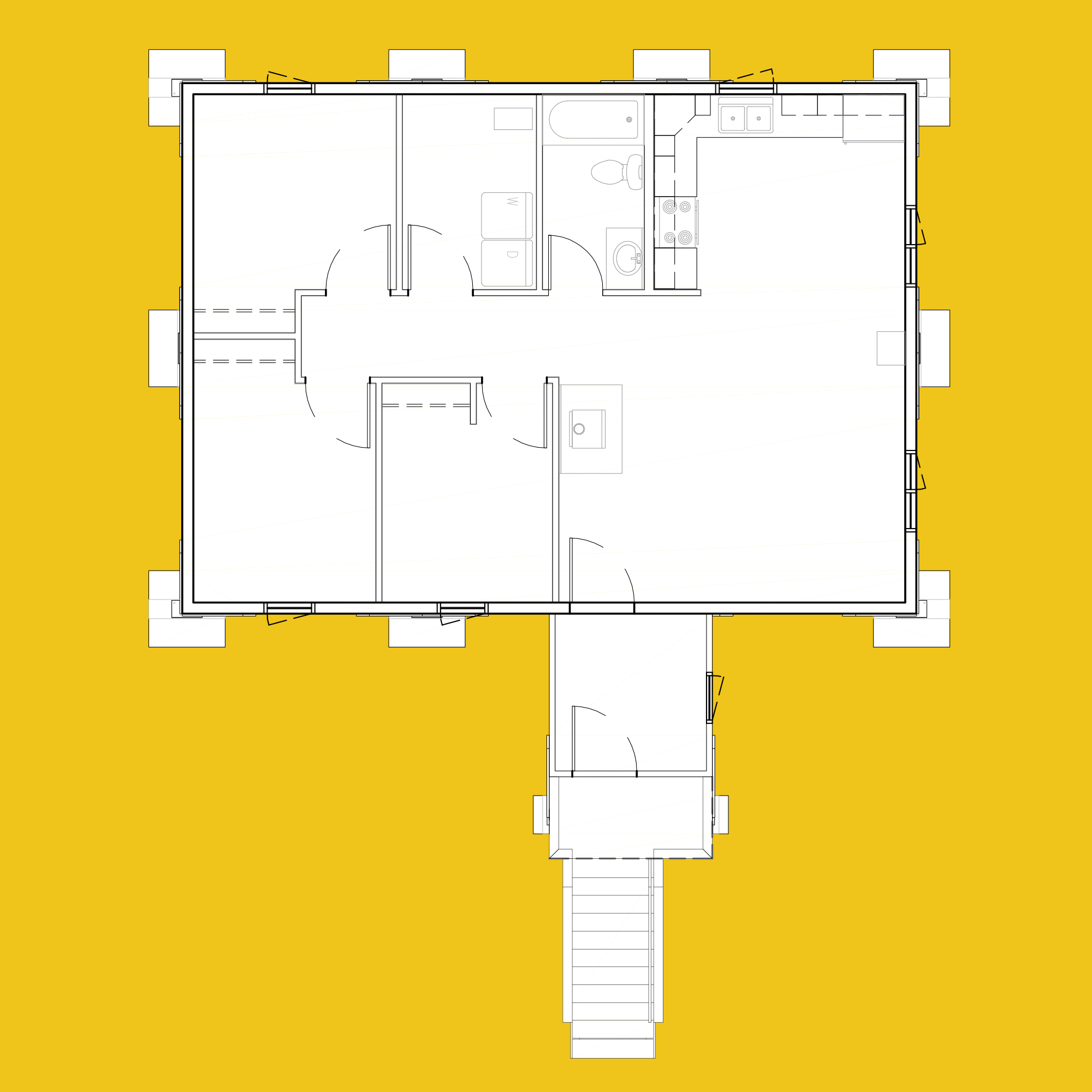

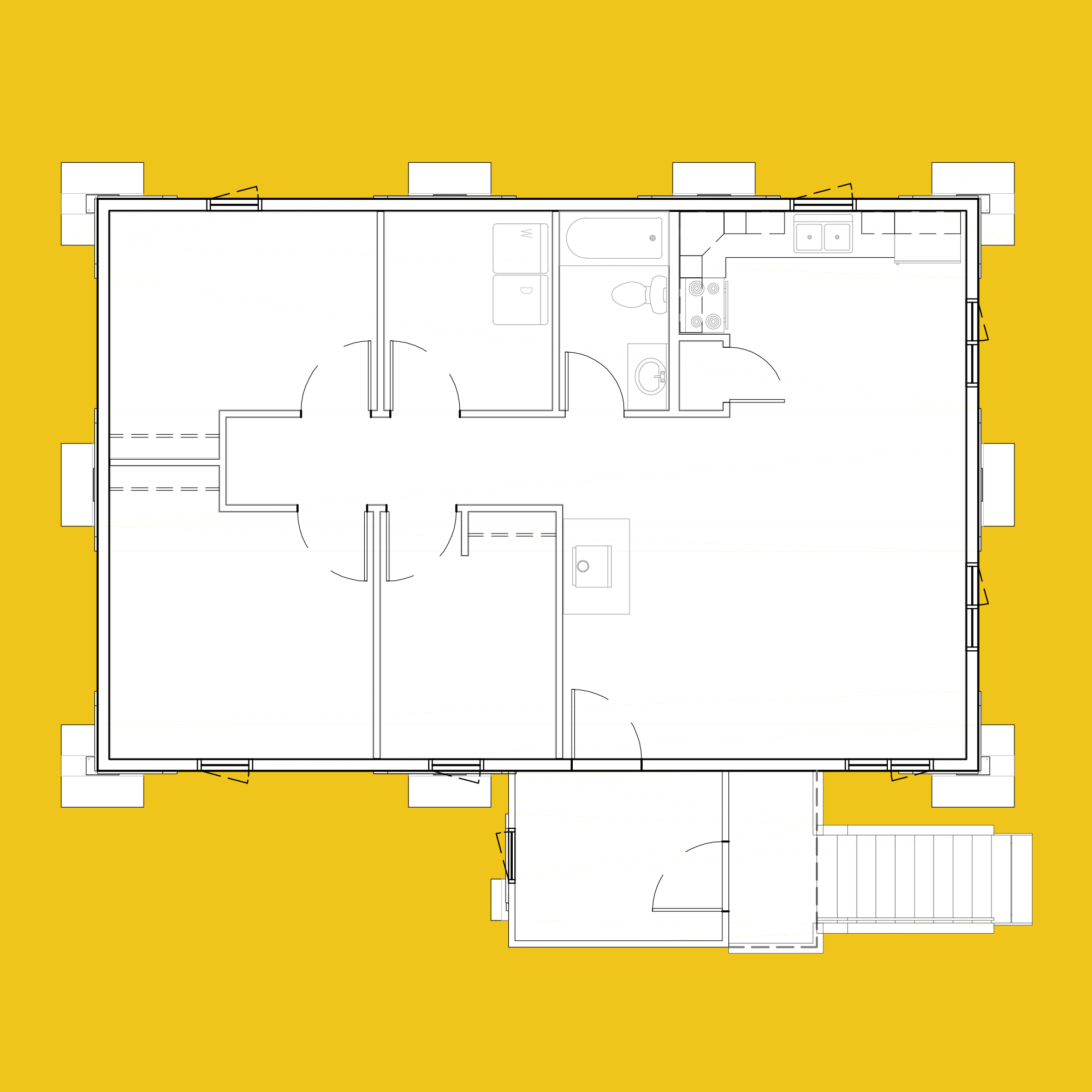

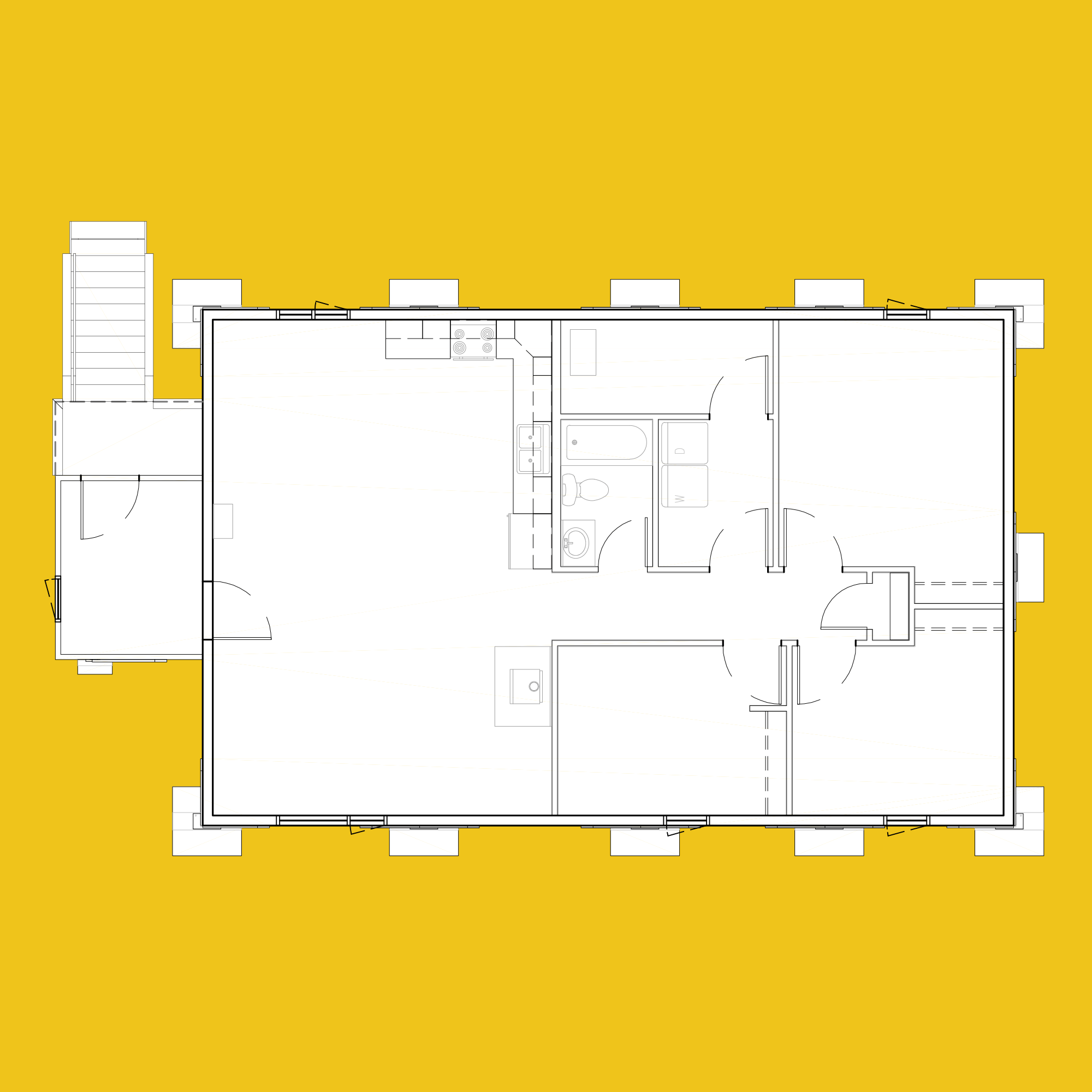

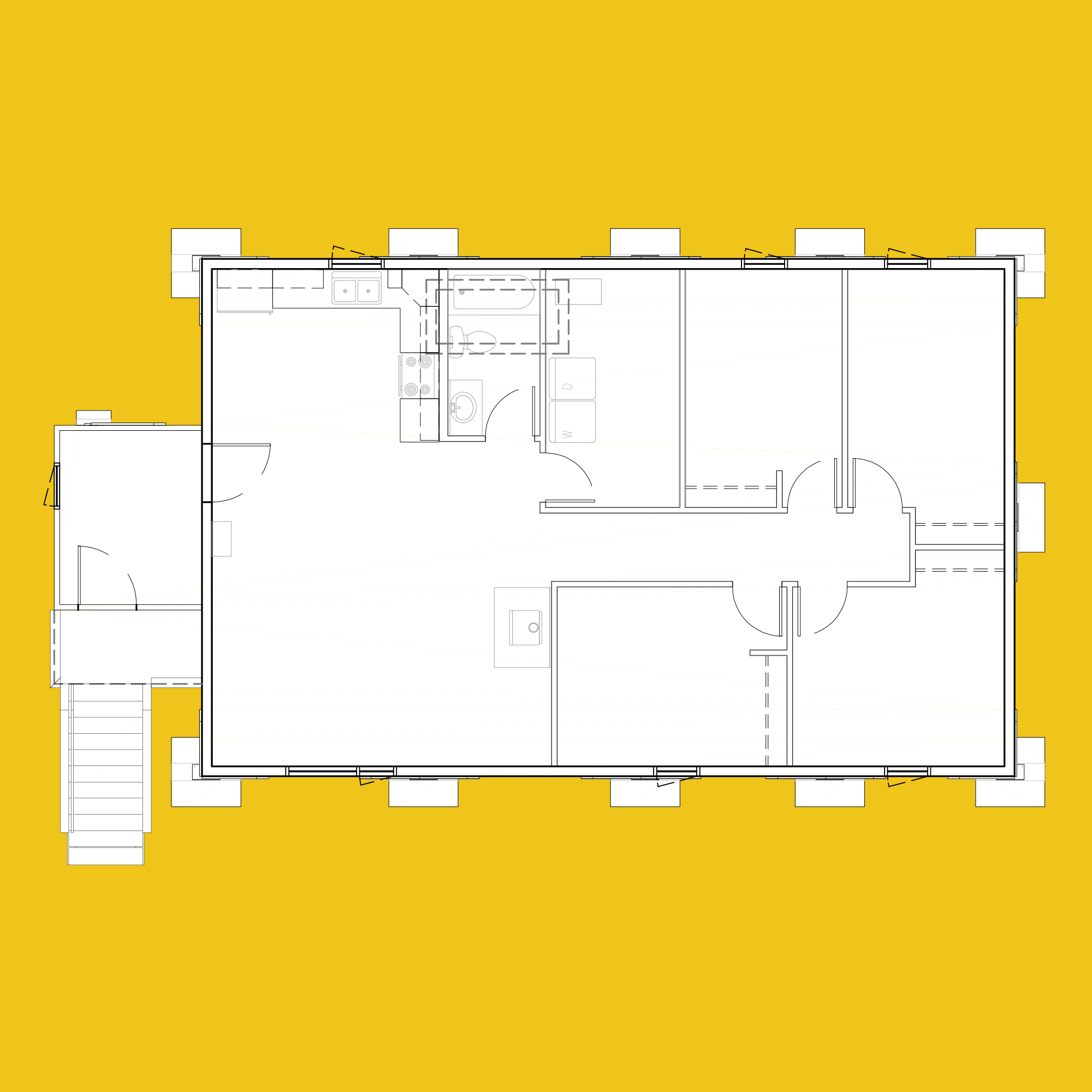

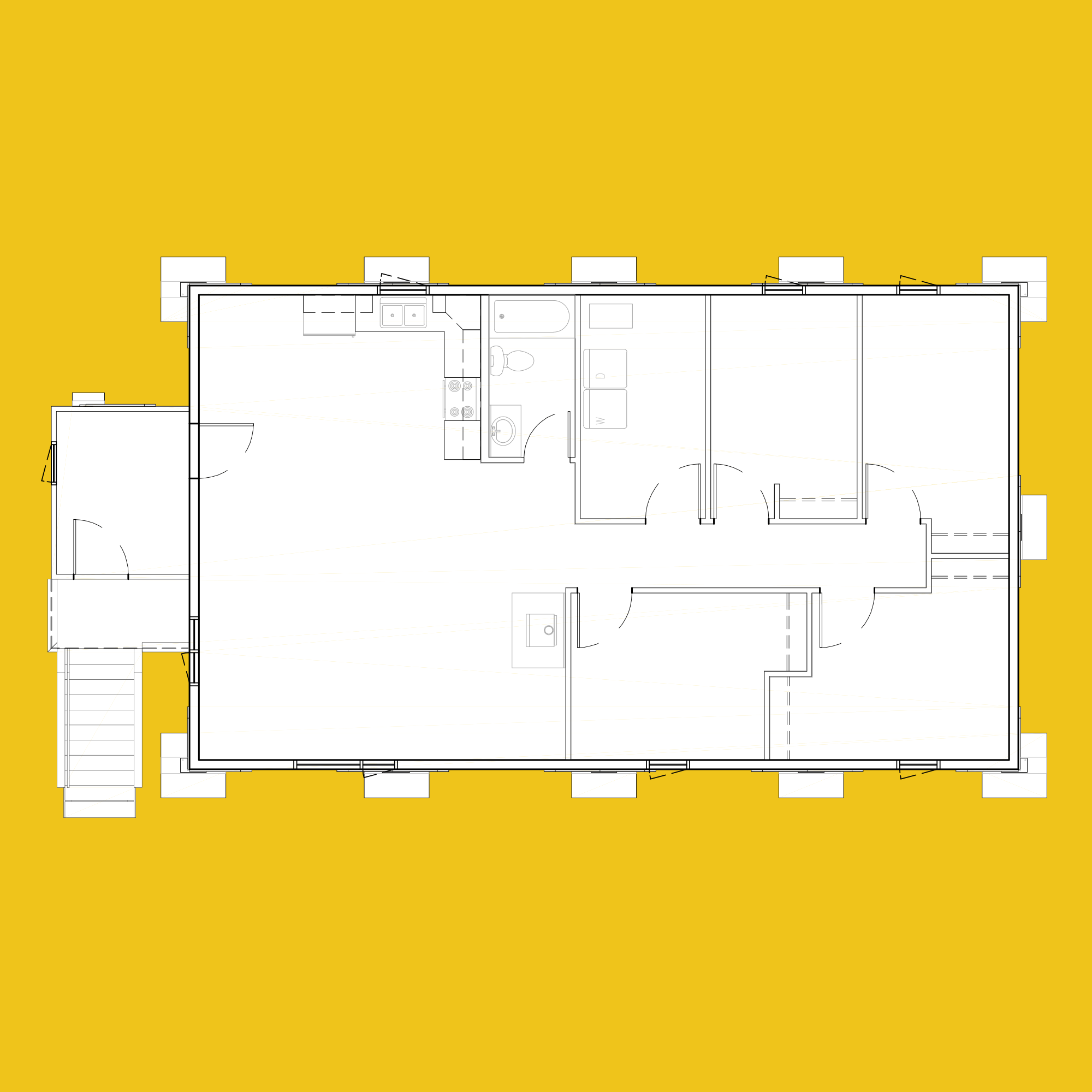

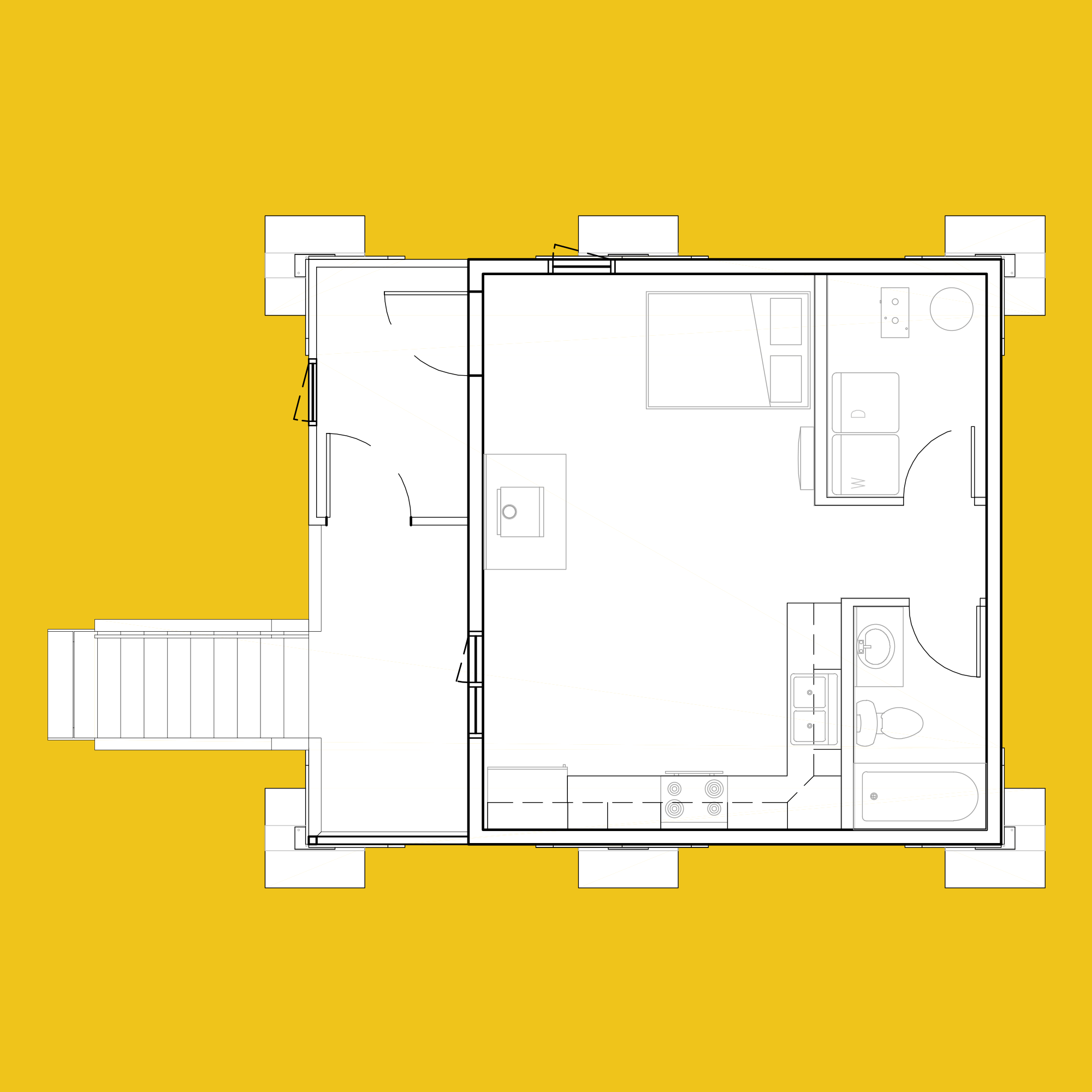

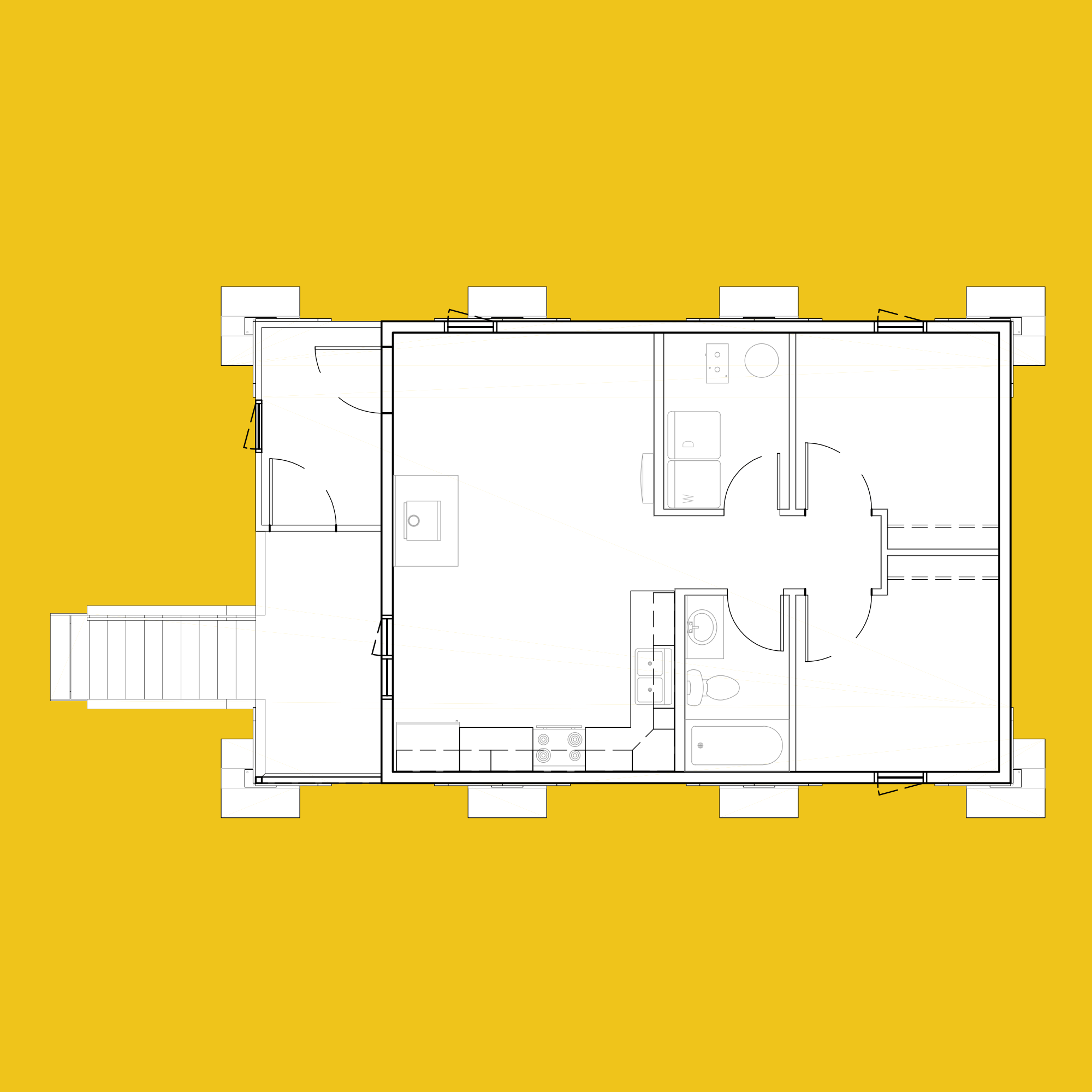

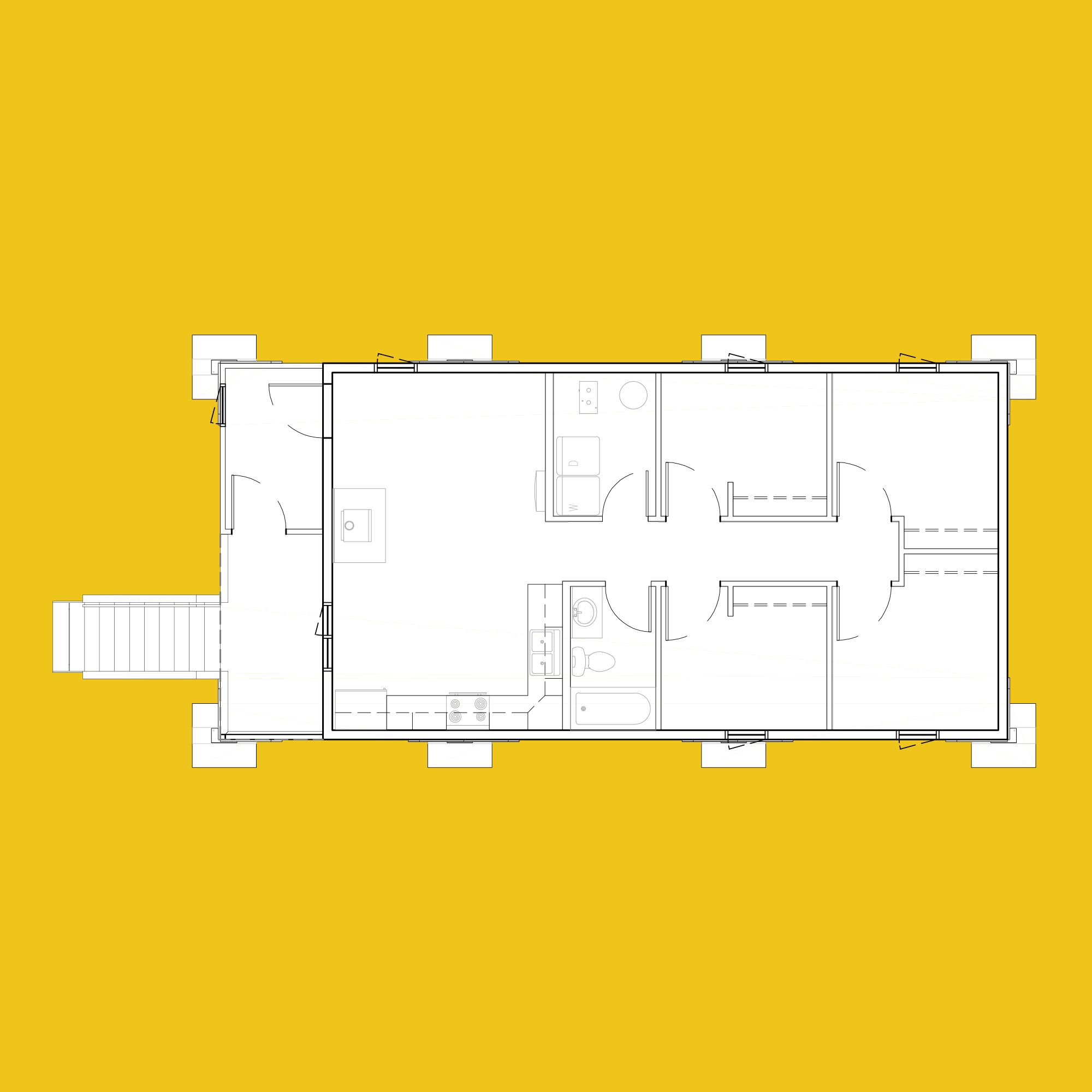

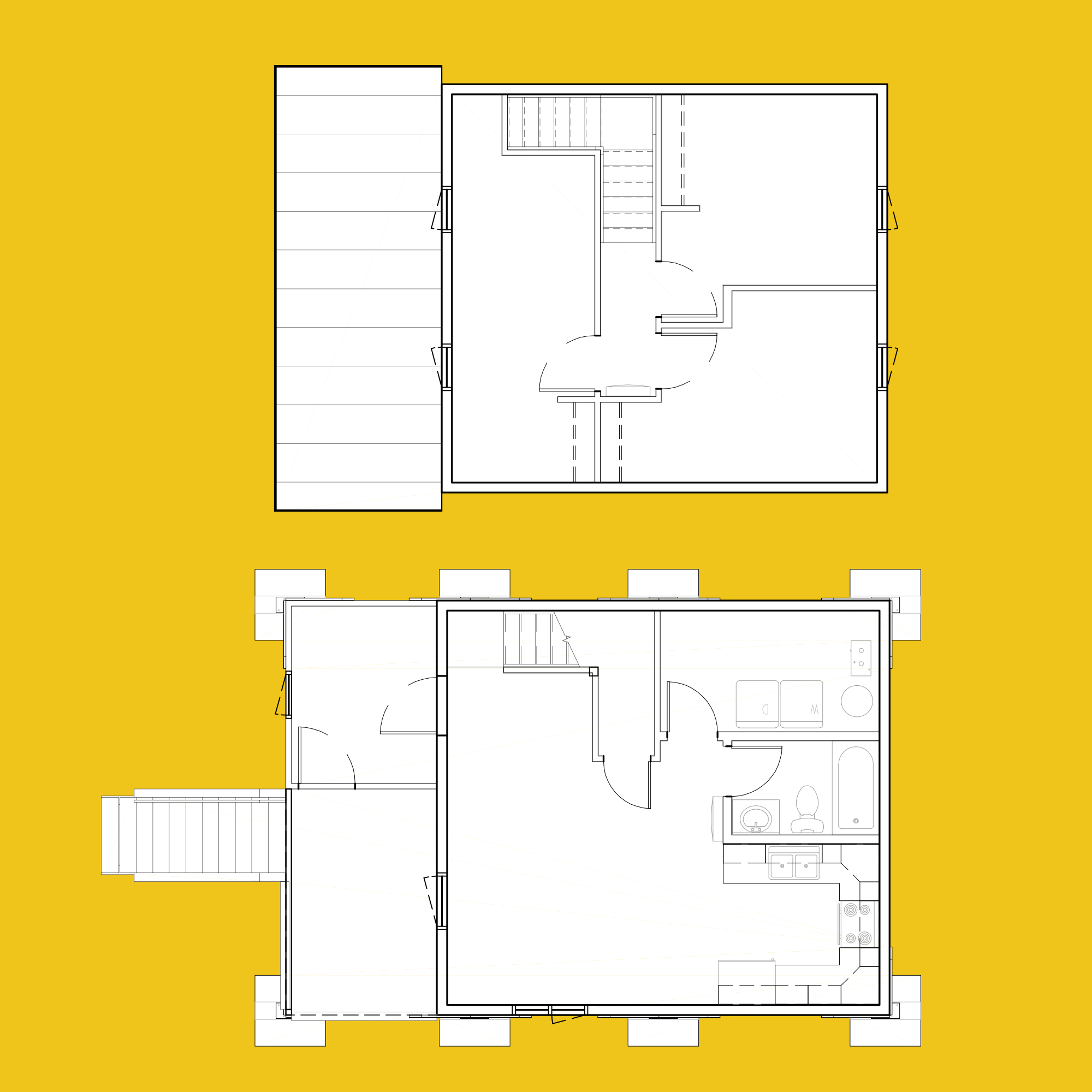

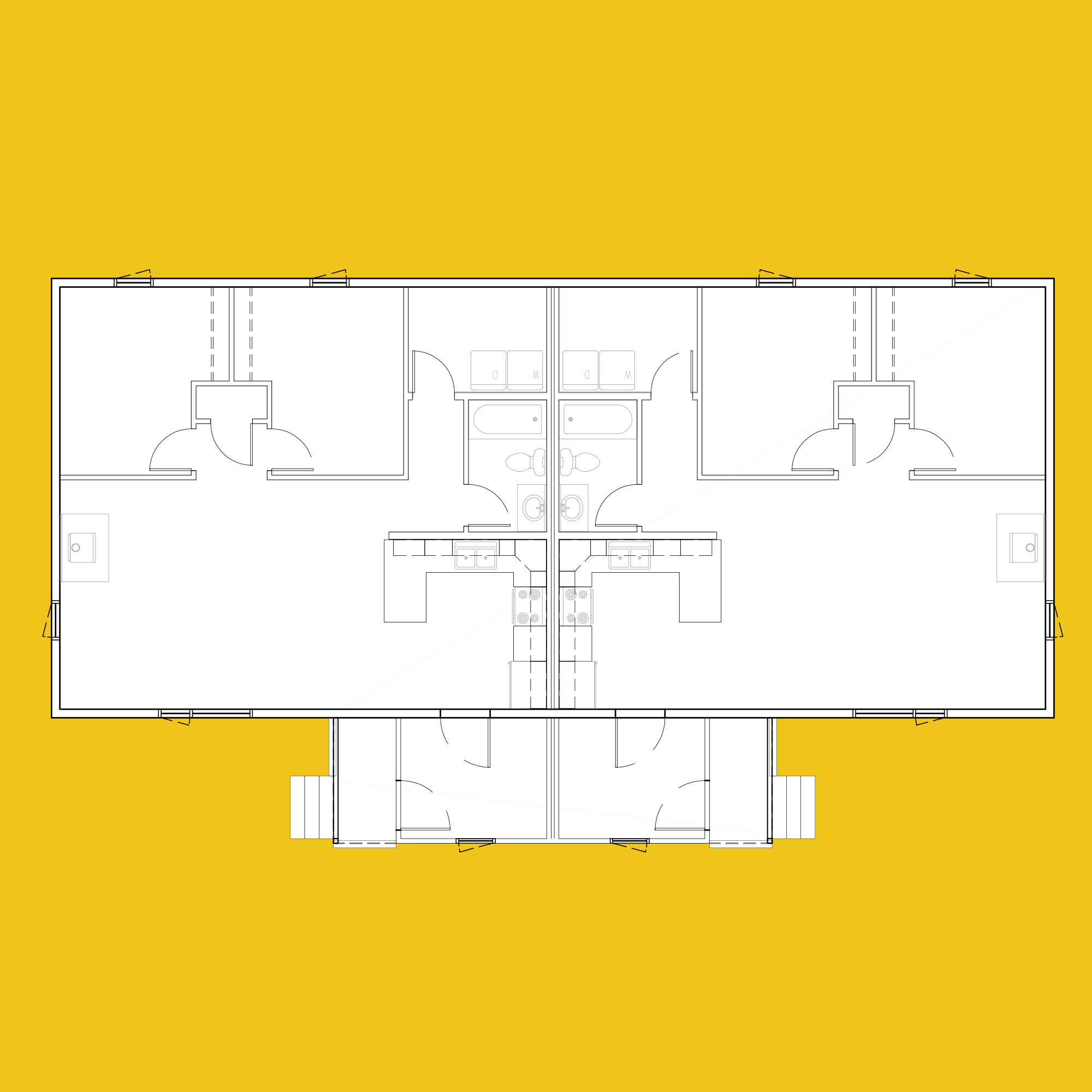

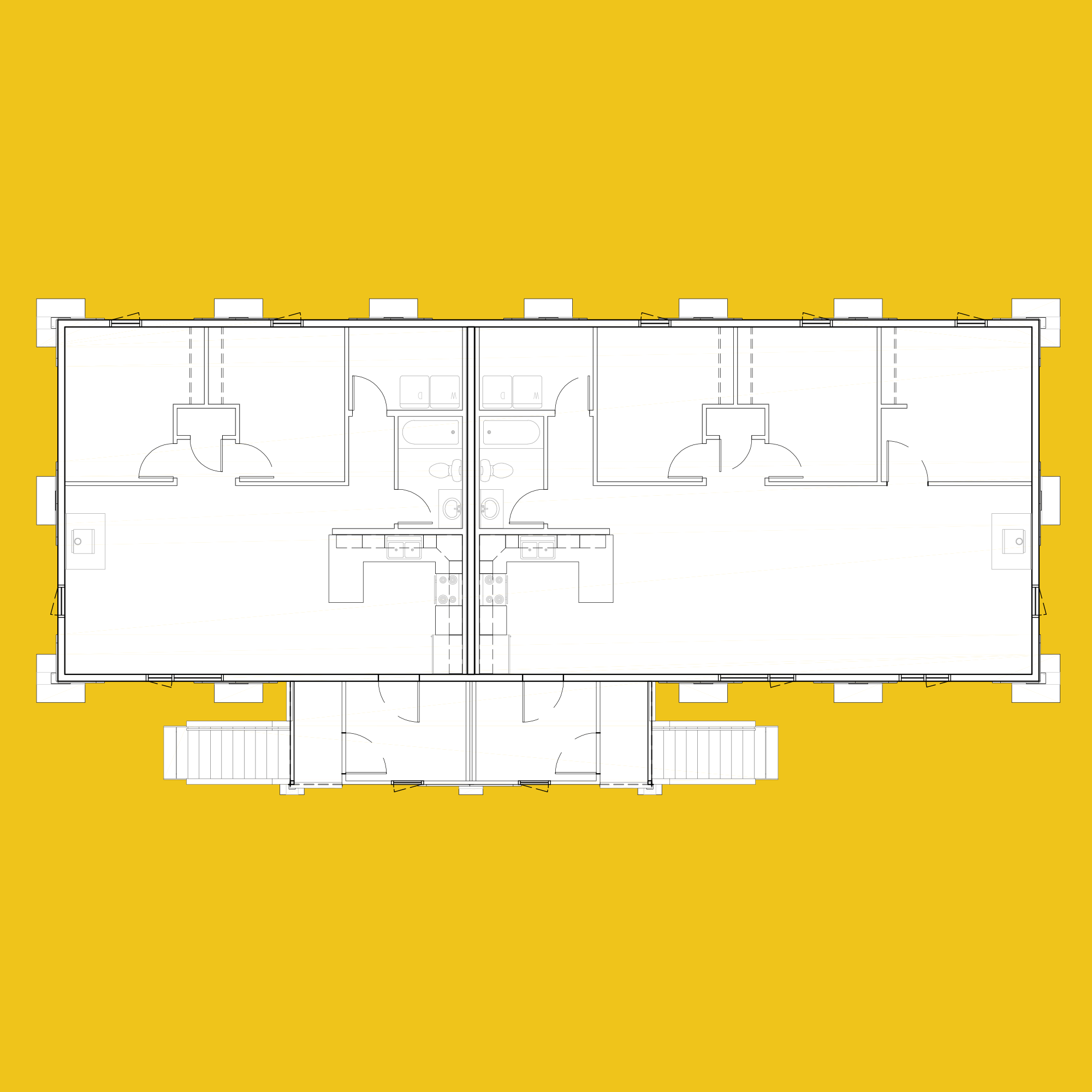

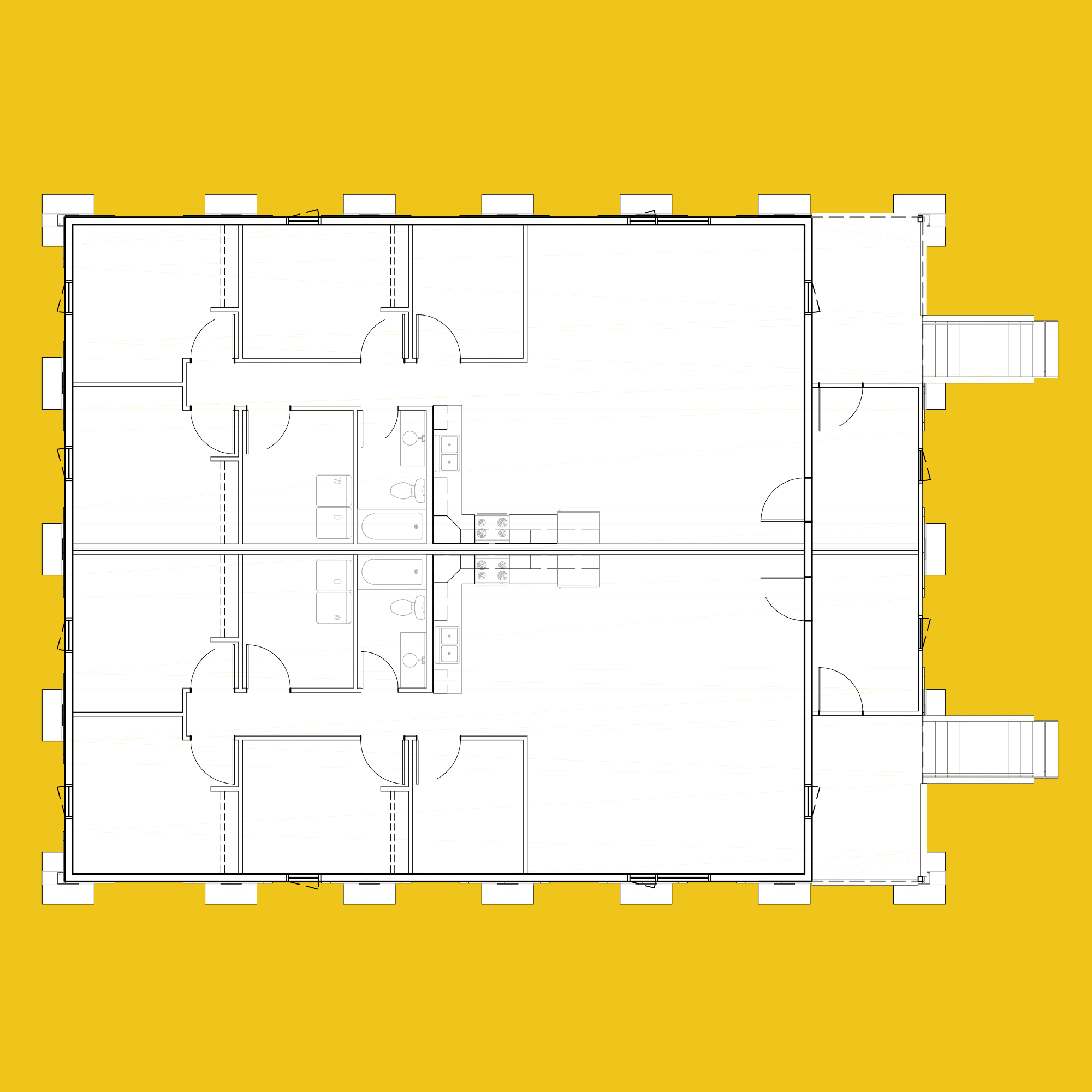

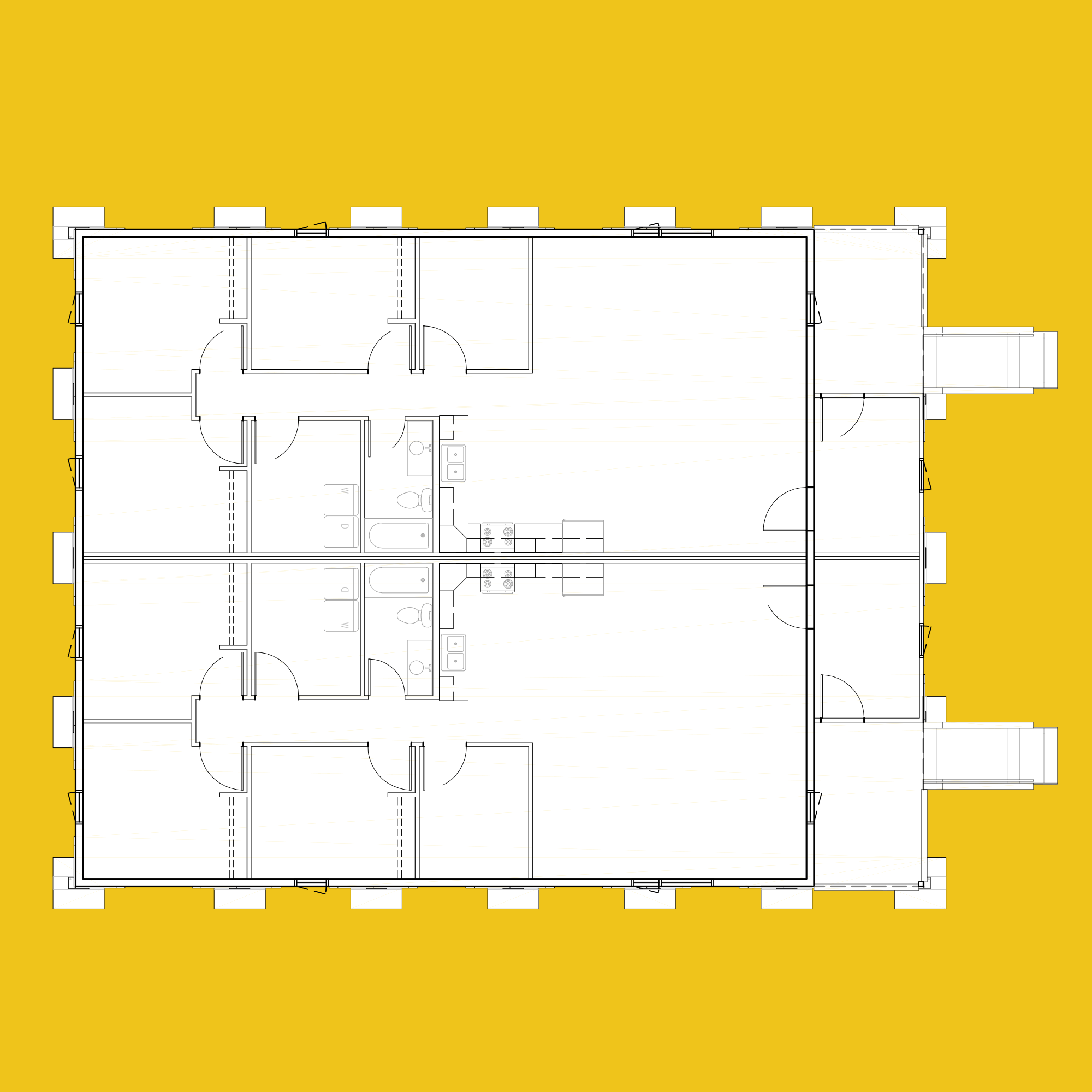

We will work with you to design and produce panels for your structure: a home, shed, cabin, commercial, hangar, and more!

CONTACT US

Alaska Insulated Panels is a leading manufacturer producing

TOP

QUALITY

structural insulated panels tailored for residential and commercial construction projects, providing exceptional energy efficiency, strength, and quality for various applications.

Our Structures in

Alaska

Alaska Insulated Panel structures already cover over 100 communities and cities in Alaska.

READY TO

BUILD

BETTER?

Bernie Vannoy

General Manager

Direct: (907) 357-2773

Bernie@alaskainsulatedpanels.com

Gary Pinckert

General Manager

Direct: (907) 357-2774

gary@alaskainsulatedpanels.com

Alaska Insulated Panels is a leading manufacturer producing top-quality structural insulated panels in Alaska tailored for residential and commercial construction projects, providing exceptional energy efficiency, strength, and quality for various applications.

(907) 357-2769 • Admin@alaskainsulatedpanels.com

301 Aspen Ave • Wasilla, AK 99654

© 2024 Alaska Insulated Panels, All Rights Reserved